-

The dough is formed into a set of specifications.

Cut the dough into pieces of required weight.

Automatic feeding to save labor force.

One of the necessary combination models to realize the automation of molding line.

more -

Vertical feeding design to preserve raw flavor of raw materials.

Can fill single filling, double filling, powder filling, granular filling (like jam) and other fillings.

Thin film key with synchronous speed regulation function, easy to operate.

Adopt imported motor and frequency converter with stable speed, stable product weight and small error.

more -

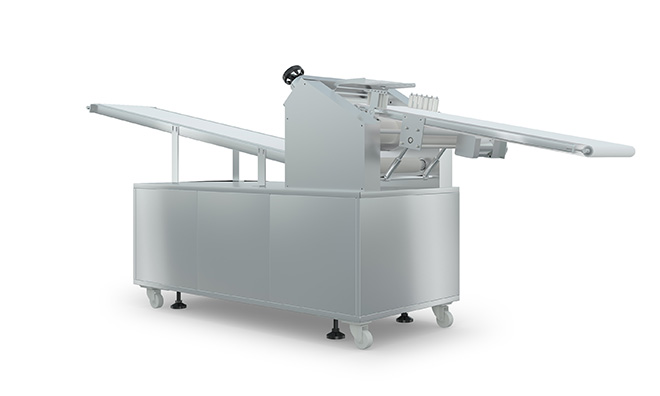

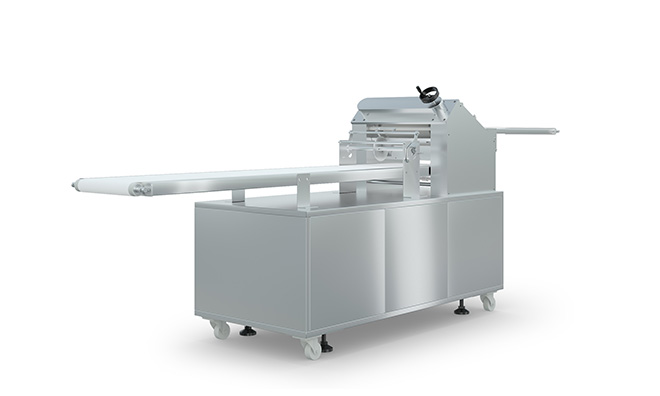

Connect pressing machine with main engine.

Initial shaping for the pressed dough and transfer to the main machine.

One of the necessary combination models to realize the automation of molding line.

more -

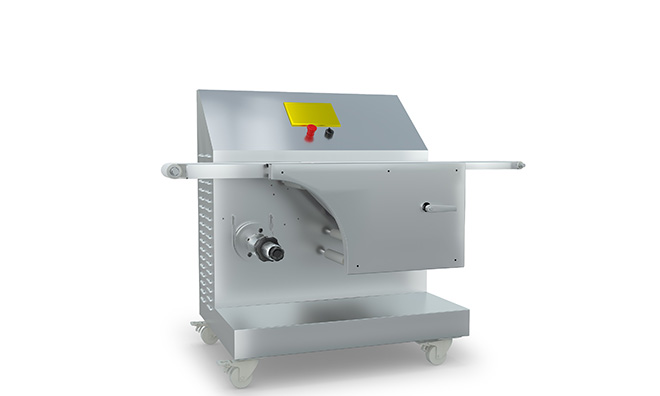

Hardened tooth reducer with low failure rate.

Low energy consumption, high efficiency, reversible turn over cylinder.

Automatic upper water system.

Can be connected to the automatic powder system.

more -

Automatic to separate and reform.

Photoelectric induction control system.

The cutting position ocan be adjusted.

The cutter can be added, and the flour belt multichip cut.

more -

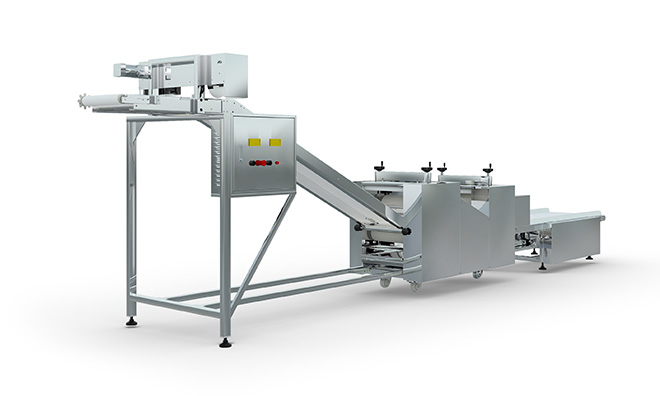

(Hand/Automatic) dynamic continuous press flour.

Adjustable output thickness of pressure flour wheel.

Automatic sprinkling system.

Automatic startup time can be set.

Add safety fence and emergency safety switch.

Available to match various types of conveyor (customizable).

S-type continuous folding delay pressing can smooth dough extension.

more -

Photoelectric induction controls the embryonic position precisely.

The pneumatic beat mould to save labor cost.

more -

It is suitable for various kinds of sauces such as meat filling, vegetable filling, bean paste, bean paste, five kernel filling, granulated fruit jam and so on.

Adopt vertical feeding design to reduce the damage to physical property and maintain the traditional manual flavor.

Easy to remove and easy to clean.

The size of feed nozzle can be changed to fit various filling and production specifications.

more -

Can set cutting length.

Adopt clutch drive design to faster, higher capacity and keep it precise.

The cutter can be customized according to customer's requirement.

A safety device provided.

more -

PLC microcomputer precision control.

Imported photoelectric sensor.

Replace artificial packing paper, the degree of automation is higher.

It is the national initiative. Paper wide can be adjustable width wide using range. It is mature and stable.

more

Hotline: 0510-81667258

EQUIPMENT

Location: Home >> EQUIPMENT